Highest purity

Electrolytic processes such as electrochemical polishing, plasma polishing and electrolytic etching enable effective cleaning and processing of metal surfaces, removing impurities and producing a smooth and uniform surface with high reproducibility.

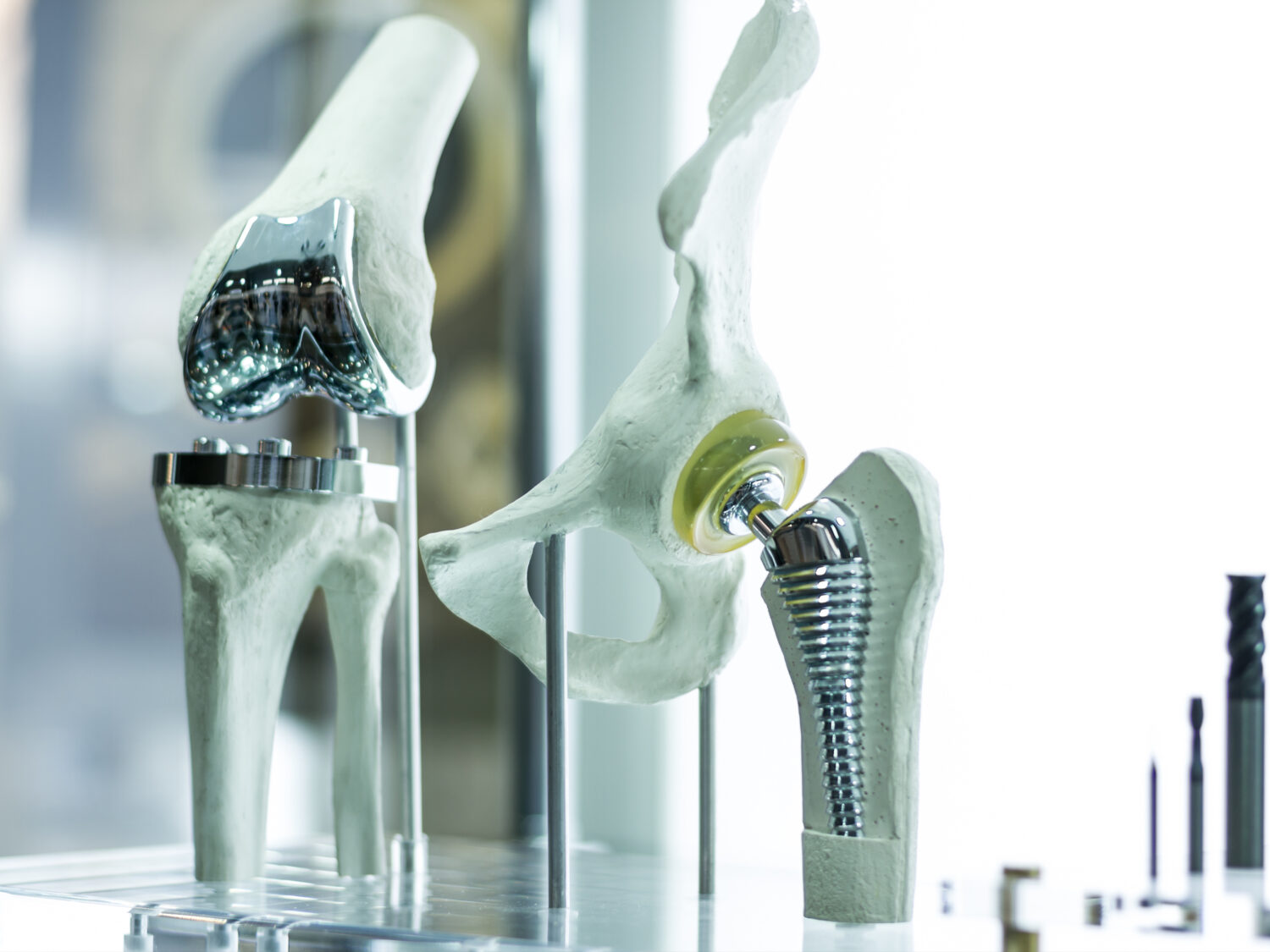

BWB Surface Technology specialises in the electrolytic polishing of stainless steel parts – from bright parts for the watch industry to pure parts for medical technology (ISO 13485) to heavily stressed parts in mechanical engineering and precision mechanics.

Electrolytic surface conversions

Locations

7500 x 1200 x 2200 mm

8000 x 750 x 2500 mm

2500 x 800 x 1000 mm

3000 x 550 x 1000 mm

3100 x 400 x 1100 mm

5000 x 800 x 1800 mm

3000 x 800 x 1500 mm

22000 x 1300 x 2000 mm

Locations

2000 x 500 x 1500 mm

400 x 450 x 1100 mm

5000 x 800 x 1800 mm

Location

5000 x 800 x 1800 mm

Locations

600 x 400 x 600 mm

1200 x 700 x 500 mm

1100 x 700 x 400 mm

Location

500 x 500 x 400 mm

Contact

Jennifer Nau

Operations Manager

+41 32 924 50 70 jennifer.nau@bwb-group.comBWB-Ampho SA

Chemin de la Combeta 3

CH-2300 La Chaux-de-Fonds

+41 32 924 50 70

Marcus Kolb

Head of Marketing and Sales

+49 351 8831 450 marcus.kolb@flugzeuggalvanik.deNehlsen-BWB Flugzeug-Galvanik Dresden GmbH & Co. KG

Grenzstraße 1a / 2

D-01109 Dresden

+49 351 8831 400

Reto Castelluccio

Operations Manager

+41 58 861 96 02 reto.castelluccio@bwb-group.comBWB-Iten AG

Bernstrasse 6

8964 Rudolfstetten

+41 58 861 96 00